Differential Expansion |

(DE) |

Controller/Safety Limit Switch |

for Cryogenic and High Temperature Applications |

||

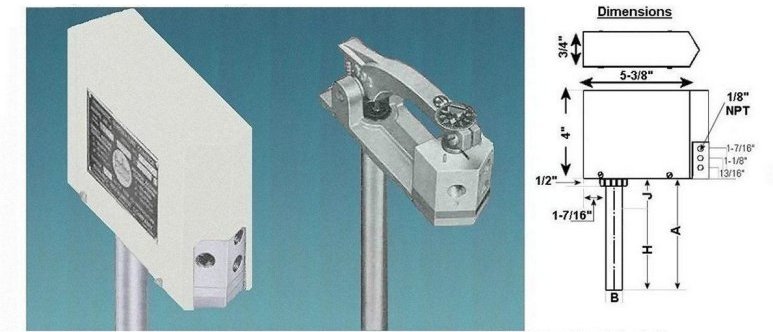

Burling Model HR-A™Pneumatic Temperature Controller provides accurate, reliable control of industrial heating and cooling installations. Specifically, it controls the opening and closing of air operated valves which in turn controls the flow of the heating or cooling media, such as gas, water, steam or cryogenic fluids. |

||

* Accessible Calibrated Dial with Security Cover |

* Provides Proportional Control |

* No External Calibration Devices Necessary |

* Direct or Reverse Acting |

| * Cost Effective | * No Leaking Capillary Tubing or Bulbs |

| * Rugged Construction | * No Thermowell Required |

| * Temperatures from -50°F to 1800°F |

Specifications |

(Subject To Change) |

Operation |

- Variable Throttling Range |

The Unit is comprised of two tubes; the outer tube has a higher coefficient of linear expansion; an increase in temperature causes the outer tube to expand more than the inner one, actuating the lever toward the valve. |

|

| Tube Construction | ||

| - Variable Overall Lengths | In most Burling Controls, the inner member is made of two sections. The section nearer the head of the unit is unaffected by gradual temperature changes. Only the far end of the tube is active. To get consistent control, it is essential that the active length be exposed to the changing temperature. The heat sensing elelement on Burling Differential expansion Controls is of an all-solid construction, with no liquid or vapor fill. | |

- Variable Active Lengths |

||

8-½" - 17" |

(Contact Factory) | Valve |

| - Manual Overide Option | The Pilot Valve is a 3-way type, with three ports, for input, output and bleed. Changing from direct to reverse action is accomplished by merely reversing connections at input and bleed. The cover does not even have to be removed. | |

| (Contact Factory) | ||

| - Various Mounting Fittings Available | Adjustments | |

| The temperature set point is changed by an internal screw on the lever. There is a small throttling range adjustment on top of the valve to allow adjustment between figures given. | ||